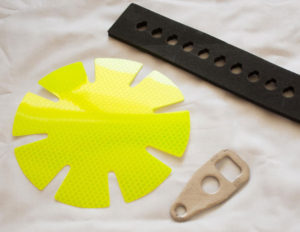

OEM Gaskets

When it comes to products that seal, absorb, cushion, dampen, insulate, shield or protect, Diamond Cutting has you covered.

We have the knowledge, skills, and quality materials you need so that your product vision can become reality. Our staff of experienced product specialists brings their abilities to assist your efforts. Our team is creative in approaches to customer needs and is adaptive to modifying manufacturing processes. We have capabilities to produce prototypes by hand fabrication, steel rule dies (as needed), and rapid computer controlled cutting process.

Diamond Cutting has instituted a Quality Assurance System to provide consistently high quality product. This also guides us toward continually improving our abilities.

Our comprehensive inventory and our network of quality product manufacturers provides excellent support to you, our customers.

OEM Capabilities

Diamond Cutting’s staff members are experienced and are problem solvers. We work closely with our customers to bring forward the best options we can with the overall goal of assisting you, our customer, to achieve your vision. Our staff and processes are postured to provide high quality products.

We offer the following:

OEM Industries

At Diamond Cutting, we pride ourselves on our ability to respond to a wide range of customer visions and product or material needs. Our staff’s extensive experience gives us an ability to serve many and varied industries.

Some OEM markets which we serve include:

ELECTRONICS

- Computers

- Communication

- Entertainment

MEDICAL PRODUCTS

MACHINERY

VEHICLES

FOOD PROCESSING EQUIPMENT

GENERAL INDUSTRIAL PRODUCTS

SPECIALTY FABRICATORS

SPORTS AND RECREATION

We are up for any manufacturer of a product which may require a converted component. Give us a try!

OEM Products/Materials

At Diamond Cutting we work with a wide range of materials and thus can assist significantly in meeting your component’s needs. Our staff is trained and has the resources to assist in exploring different materials as well as assisting in their selection and processing methods.

The list below summarizes some of the materials Diamond Cutting commonly works with:

PLASTICS

- HD PE

- UHMW PE

- PVC

- Polypropylene

- Phenolics

- Mylar®

- Lexan®

- Nylon®

SPONGE, FOAM & CELLULAR PRODUCTS

- Neoprene

- Silicone

- EVA

- Urethane

- Close & Open Cell Sponge & Foam

OEM SERVICES

Diamond Cutting’s trained staff has over 40 combined years’ experience in the industry. As a result, our background provides a solid platform for solving problems. Our communication with our customers is based upon a commitment to determine their vision and their needs. Meeting their vision is our primary objective.

Diamond Cutting provides the following services:

- Design Assistance

- Broad-based Inventory

- In Depth Supplier Network

- Specialty Converting and Fabricating

- Order Fulfillment

- Short and Long Production Runs

- Custom Component Kits

- Custom or Special Packaging

- Quick Prototyping

- Adhesive Application

- Kiss-Cutting

- Optimal Nesting and Product Utilization

- Traceability

- Certification

- Just In Time delivery – JIT